Practical Information

Everything you need to know about our working methods, insulated glazing options, warranty and frequently asked questions. Have a specific question? Please get in touch.

Process

From first contact to delivery, each commission goes through a number of steps.

Enquiry

You contact us by email with your question or requirements, along with photos and measurements. A visit to the workshop is also possible.

Assessment

We review the photos and request additional information if needed.

Quotation

You receive a no-obligation quotation for the supply of stained glass windows/work.

Agreement & Planning

Upon agreement, we schedule the work and discuss delivery.

Execution

The stained glass is made or restored in our workshop.

Insulation (optional)

If desired, we have the panel incorporated into insulated glazing by a specialist manufacturer.

Delivery

Collection from the workshop or delivery, or delivered on-site regionally.

Lead Times

| Standard repair/restoration | 2–3 weeks |

| New stained glass basic/simple design, single items | 3–4 weeks |

| New stained glass elaborate, multiple windows | 4–8 weeks |

| Incorporation into insulated glazing | + approx. 4 weeks |

| Large or complex project | 2–6 months |

Lead times are indicative and dependent on scheduling and material availability.

Delivery

You can drop off and collect your stained glass at our workshop. For larger projects in the region, we can also collect or deliver.

Packaging

We supply stained glass panels well protected with cardboard corners and wrapping. For transport in a car, lay panels flat or secure them upright. Avoid pressure on the glass surface.

Insulated Glazing Specifications

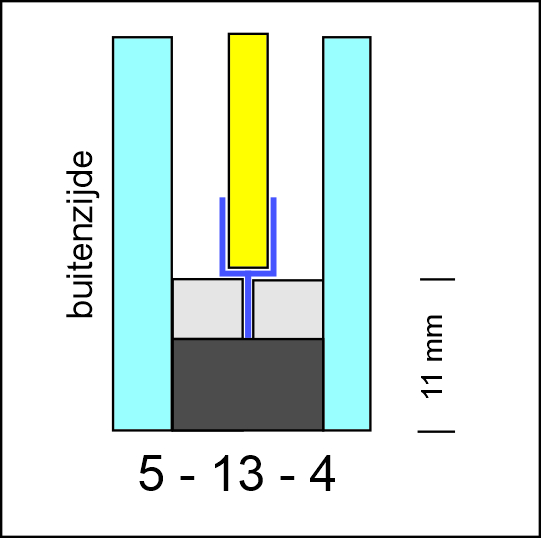

Stained glass can be incorporated into various types of insulated glazing. Below are the most common options.

Standard Composition

| Type | Composition | Total thickness |

|---|---|---|

| Standard | 5-13-4 | approx. 22mm |

| HR Argon | 5-13-4hr Argon | approx. 22mm |

| Laminated glass | 5-13-33.1 | approx. 24mm |

| Laminated glass HR | 5-13-33.1hr Argon | approx. 24mm |

Laminated glass (33.1) – In case of breakage, the shards remain attached to the foil. Injury-reducing, burglary-resistant, blocks UV radiation and reduces sound. Can be applied on the inside, outside or both sides.

Explanation

- HR coating (#1.1) – Reflects heat back inside, significantly improves insulation value

- Argon gas filling – Improves insulation compared to air in the cavity

What fits in your frame?

In modern frames with double-glazing rebate, insulated stained glass usually fits without modifications. For authentic or narrower rebates, a glazier, carpenter or contractor can advise on any necessary adjustments.

Cavity widths

Available cavity widths (space between glass panes): 4, 6, 8, 9, 10, 12, 13, 14, 15, 16, 18 and 20mm. Available in plain or black aluminium spacer.

Note: cavity width 13mm = 2× frame 6mm + 1mm for stained glass Y-profile.

Warranty

We provide warranty on our workmanship. This covers defects in construction, soldering and cementing/puttying.

Not Covered

- Damage from external causes (impact, vandalism, storm)

- Normal wear of the lead over time

- Characteristics of antique glass (bubbles, streaks, thickness variations)

- Colour differences in replacement glass compared to existing glass

Insulated Glazing

For insulated glazing, the manufacturer's warranty applies. This is usually 10 years against fogging (failure of the seal).

Service Area

Our workshop is located in the centre of Haarlem. We primarily work on projects in Haarlem and the surrounding area, but also carry out work throughout The Netherlands and occasionally abroad.

Collection and Delivery

- Haarlem and environs – Collection and delivery by arrangement

- Rest of The Netherlands – Delivery and collection can be arranged

- International – Shipping by arrangement, or collection from the workshop

Stained Glass Terminology

A brief explanation of common terms in stained glass.

General Terms

- Stained glass / Leaded glass

- Decorative glazing where pieces of glass are joined together with lead strips (came).

- Lead came

- H-shaped lead profile in which the glass pieces are clamped. Available in various widths.

- Soldering

- Joining the lead strips at intersections with tin solder.

- Cementing / Puttying

- Applying cement (putty) to make the glass wind and watertight in the lead.

- Patina / Patinating

- The dark discolouration of lead and solder that occurs through aging or chemical treatment. Desired in restoration for an authentic appearance.

Lead Profiles

- H-profile (came)

- Standard H-shaped lead profile in which the glass is clamped. Common widths: 6, 7, 8, 10 or 12mm.

- U-profile (edge came)

- Profile for the edges of a panel, with one arm facing outward.

- Steel-core lead

- Lead profile with steel core for extra rigidity in large panels.

- Saddle bars

- External reinforcement of stained glass panels, usually metal bars against wind pressure.

Glass Types

- Antique glass

- Mouth-blown glass with characteristic irregularities: air bubbles, streaks, thickness variations. Authentic for restoration.

- Cathedral glass

- Hand or machine-made textured glass. Translucent with texture, available in various colours.

- Float glass (clear glass)

- Modern, clear flat glass without irregularities.

- Figured glass

- Glass with relief pattern, such as water glass or ice flowers.

Measurements

- Daylight opening

- The clear opening in the frame (inside to inside).

- Rebate size

- The measurement of the recess where the glass is placed.

- Rebate depth

- How deep the glass can go into the frame. Determines whether insulated glazing fits.

- Glass size

- The size of the stained glass panel itself (outside of lead profile).

- Insulated glazing size

- The total size of the insulated glass unit containing the stained glass. Usually daylight opening + 22mm.

Characteristics of Antique Glass

Old and antique glass has characteristic irregularities. These are not defects, but desirable properties that give the glass its authentic appearance:

- Air bubbles – Small bubbles in the glass

- Streaks or veins – Fine lines from blowing or drawing

- Thickness variation – Glass not uniformly thick

- Ripples – Slightly distorted view when looking through

- Uneven surface – Small pits, scratches or matt spots

We do not provide guarantees on these characteristics of old/antique glass.